Pipe Threading & Cutting

Pipe Threading & Cutting

Electrical Pipe Threading & Cutting Services in New England

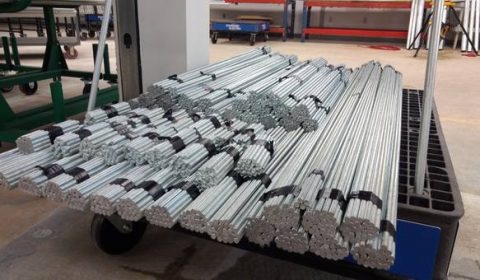

Are you looking for customized pipe cutting and threading for your business? If so, we can help. HZ Electric Supply offers complete pipe fabrication for all types of commercial and industrial applications. We offer pipe threading services with pipe diameters ranging from ½” through 6”. We can custom cut and thread to your specifications, and work with materials including intermediate metallic conduit, galvanized rigid conduit, PVC-coated GRC (OCAL, ROB ROY, PERMA COAT), aluminum rigid conduit, and schedule 40 black pipe.

Place your order today by calling 413-734-6407 or contacting us online here. We serve northeast territories, including Massachusetts, New York, and Connecticut.

Types of Material We Can Cut

Get a Free Estimate Today on Our Cutting and Threading Services

HZ Electric Supply has the right quality service or product for you regardless of your needs. We offer complete pipe cutting and threading services throughout New England & New York State. Contact our Solutions team today to get an estimate by filling out our form here or emailing solutionsr22a@usesi.com.

Pipe CUTTING & THREADING FAQ's

Today’s pipe-bending processes are too often characterized by inaccuracy, inefficiency, costly labor, and material waste. Many times we see a “Bone Yard” on job sites. However, with the new AutoBend 3D, EW-CT can now help our customers by bending their pipe to be uniform and precise each time

Ryan Cruz will manage the Pipe Bender, a Licensed Journeyman Electrician with 16 years of electrical contracting under his belt.

We can bend EMT, Rigid, IMC, Stainless, and Aluminum Rigid pipe. We are unable to bend PVC and PVC Coated pipe.

We can bend ½-inch up to 4-inch pipe.

Yes, in rigid-type pipe we can supply special radius bends. However, we are unable to provide this for EMT bends.

It works with “Revit” and “Greenlee Bendworks”.

EW-CT has created a simple form for customers to send in their bend requests. We also accept Revit or Bendworks files. Get in touch with a Solutions Manager for more details (see below).

- How fast can we have our order ready for pick up or delivery?

If ordered by 11:00 am, orders fewer than 20 bends can be delivered the next day. Lead times will be dependent on the current workload. *Special Restrictions may apply. - Will it bend plumbing pipe or mechanical pipe?

No, we are only able to bend electrical pipe. - How does EW-CT deliver the bent pipe?

EW-CT has had specialized carts made to ensure transportation and delivery of the bent pipe will make it to your job site safely without damage. *Special restrictions apply. - If I have questions, may I come to see the AutoBend and what it can do?

Yes, we can arrange a demo. Get in touch with a Solutions Manager for more details (see below).

case studies

Wire Solution Case Studies

View our job site labor and cost-saving case studies. Learn how much you can save with our Southwire Solution services!

- SIMpull REEL™ Case Study

- SIMpull REEL™ with Puller Case Study

- REEL™ Solutions Truck Case Study

OUR PREFAB OFFERINGS

Bending